How it all started

WATER

Why is water already in a can of paint?

Why has water been transported in a can for years? No less than 60% of the content of a can of paint consists of water.

Why can’t water be added at the moment of actually painting?

POWDER

These questions were the starting point for setting up the company RAW Paints in 2015.

In the course of two years a formula was developed from powders, with the addition of water, becomes a quality paint for walls. Quality that is reflected on the wall and does not have to prove itself in a paint can. RAW Paints has developed various formulas for all types of walls, inside and outside and various applications, such as cellars.

TEST

Our first project was the ultimate test; on the boulevard of Zandvoort our first formula was exposed to salty air, wind, sand and sun.

Several projects followed to test and adjust our formulas.

By painting ourselves with our paint formulas we learned to know our product better, we listened to the pain points of the consumer and we got insight into the paint industry.

THEORY TEST

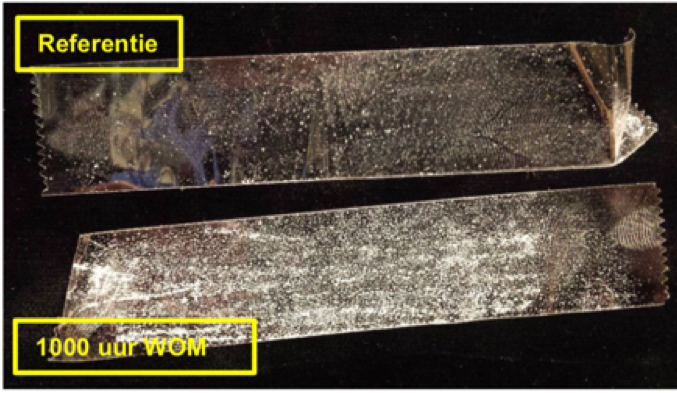

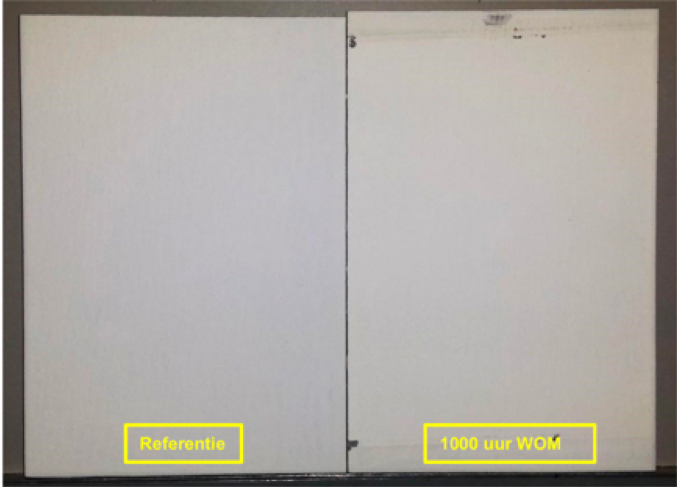

Through a TNO test on adhesion and UV resistance we were classified as a Class 1 paint.

UNIQUE FEATURES

- It is a mineral paint powder, made from mineral raw materials

- The paint powder contains raw materials which is waste in other industries; a step towards circular economy

- The paint powder does not contain solvents

- The paint powder once created with water allows for the substrate to be absorbed (if minerals/stones are untreated) and therefore does not peel off

- The paint ensures adhesion to walls that suffer from a high moisture percentage in the stone

SINCE 2016 AN EXTENSIVE PRODUCT PORTFOLIO

- cellar paint – BASEPAINT

- interior paint – OMBREWALL

- façade paint for ordinary and damp substrates – RWP028

- bathroom paint – STEAM

- concrete paint – CONTRETE

- roof paint – ROOFTOPCOAT

RAW Paints & SDGs

Good health: no use of titanium dioxide, preservatives and pesticides – better for producer, painter and consumer.

SDG 6:

Because we have no water in our production and therefore do not create waste water that needs to be purified, no waste water goes into the groundwater.

SDG 9:

Our product is disruptive in the industry: the entire paint industry produces liquid paint – we powdered – this is much better for people, the environment and the planet. In addition, our products attach better to the surface where competition unleashes on e.g. moist surfaces.

SDG 11:

By using, for example, our roof paint, we make our cities liveable – ROOFTOPCOAT provides cooler roofs and thus a more pleasant living environment.

SDG 12:

With our products you only mix what you need and there is no question of residual paint (20% of paint is never used again and must be burned).

SDG 13:

By switching directly to powder production, you reduce CO2 emissions in production and transport.

SDG 14:

Because of the lack of water in the production process, there is no waste water and no additives are added that are harmful to life in water. Through smart use in packaging and always wanting to be innovative, we go to a no wast packaging.

SDG 15:

We try to apply as many ingredients as possible in our products that are residual material in another industry.

SDG 17:

By working together with multiple networks and partners, a broader base is created to switch from liquid paint to powder paint.

Click here for our partners